When demand spikes, the shops that thrive aren’t always the ones with the biggest machines. They’re the ones that keep spindles cutting, hour after hour, without drama. That’s the promise of CNC milling automation: more parts per shift, consistent quality, and predictable costs. If you’re chasing tight deadlines, tight tolerances, and better margins, automation isn’t just nice to have. It’s the operating system for modern production.

What “Automation” Really Means on a Mill

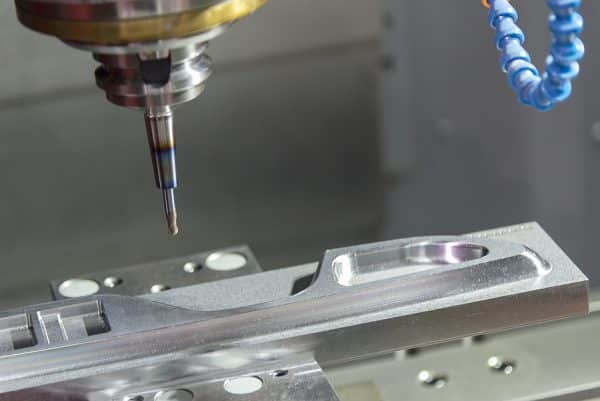

Automation isn’t one thing. It’s a stack of smart, practical upgrades that remove friction from your process:

- Robotic load/unload to handle raw stock and finished parts without pausing the spindle.

- Pallet and tombstone systems that pre-stage multiple setups and let you run families of parts.

- In-process probing and tool measurement to catch drift early and keep dimensions dead-center.

- High-capacity tool magazines with tool-life management and automatic sister tools.

- Integrated coolant and chip evacuation so your cycle keeps humming, not clogging.

Put these pieces together, and you unlock the real win: longer unattended windows, from break coverage to true lights-out. That’s where CNC milling automation solutions shine, turning nights and weekends into productive hours without burning out your team.

The Quality Advantage (Not Just the Quantity)

People often focus on throughput, but automation is a quality play, too. In-process probing checks a datum, updates the work offset, and the cut stays centered. Tool break detection swaps in a sister tool before scrap happens. Consistent clamping force from quick-change vises keeps variation out of the stack. Result: capability indexes that make your quality lead smile, fewer MRBs, and customers who stop asking for extra inspection data because the trend charts already look rock solid.

Fixtures: Where the Magic Starts

Nothing torpedoes a promising cell faster than a fussy fixture. High-volume success starts with fixturing that is:

- Rigid and repeatable. Zero-point systems let you drop on, lock in, and cut with confidence.

- Operator-proof. Clear orientation, positive stops, and error-proofing pins prevent mix-ups.

- Probe-friendly. Leave a clean shot for touch probes so offsets can update mid-run.

- Chips and coolant should clear easily, fasteners should be accessible, and wear parts should swap in minutes.

Design fixtures for the flow as much as the cut. If load/unload takes longer than the cycle, you’ll never reach your uptime goals.

Cycle Time Isn’t Everything—Uptime Is

Shops love to shave seconds, but the real KPI is spindle utilization. A five-minute cycle that runs uninterrupted for 10 hours beats a four-minute cycle that stops every 30 minutes. Good CNC milling automation focuses on the dead time between cuts: faster pallet swaps, smarter tool staging, automated chip control, and scheduled maintenance windows. Track OEE, MTBF, and MTTR like you track Cpk. If you remove the reasons a machine stops, the parts add up on their own.

Data That Pays for Itself

You can’t fix what you can’t see. Start by tying your cells to basic machine monitoring and SPC so your team gets the right signals at the right time. With live status and alarms, leads can react before a small pause snowballs into a full outage. Tool-life analytics highlight where the real wear happens, helping you set rational limits instead of guessing. And SPC dashboards surface trends days, sometimes a week, before you drift out of spec.

This isn’t about fancy software. It’s about simple, actionable visibility that keeps production smooth and predictable.

Lights-Out, the Right Way

Running unattended isn’t just “turn off the lights and hope.” It’s a checklist:

- Stable process and proven program.

- Conservative toolpaths for long runs.

- Sister tools and load-balanced wear.

- Robust chip evacuation and coolant management.

- Probing routines at the start and mid-run.

- Clear stop conditions that park the spindle safely.

Do those six, and lights-out becomes routine instead of risky.

People Still Matter

Automation doesn’t replace good machinists; it amplifies them. Your best programmers, setup techs, and deburr leads remove variation upfront, then the cell repeats that excellence all night. Cross-train operators to manage robots, pallets, and basic troubleshooting. Give them clear dashboards, clean work areas, and ownership of the metrics. Morale improves when the work is organized, and output skyrockets when the team trusts the process.

A Practical Path to ROI

Worried about the price tag? Start small and focused. Pick a narrow, high-runner part family and a short list of pain points, excess handling, tool-life surprises, and weekend bottlenecks. Pilot a tight stack of CNC milling automation solutions, like a pallet system paired with in-process probing and tool-life management. Prove the gains on that slice of work, then scale what works.

The wins usually land in three places. First, labor efficiency: one operator can keep an eye on multiple spindles instead of babysitting a single machine. Second, scrap reduction: probing and stable fixturing hold parts in spec, so fewer pieces get tossed. Third, delivery performance: those extra unattended hours soak up rush orders without piling on overtime.

Customers notice when lead times tighten and quality becomes boringly consistent. That’s how smart automation turns into repeat business.

Common Pitfalls (and How to Avoid Them)

Don’t chase aggressive cycle times out of the gate. Stabilize the process first, then dial up the speed. Keep your robot routines uncomplicated, short paths, simple sensors, and easy recovery steps, and beat flashy moves that are hard to troubleshoot. And don’t ignore chip control; pack a pocket once and you’ll lose a whole shift digging it out.

Skip the one-off fixtures for every part. Standardize base plates and clamps so repeatability scales as you add work. Fix these fundamentals early, and your automation will run like clockwork instead of a science project.

Ready to Scale Without the Stress?

If you’re ready to turn uptime into your competitive edge, we’re here to help—from fixture strategy and probing logic to full palletized cells with robots. Let’s map a realistic, step-by-step plan that fits your parts, your volumes, and your budget.

Talk with C. Thorrez Industries, Inc. about CNC milling automation: Request a consultation.