If you design or source long, slender components, you’ve probably wrestled with deflection, chatter, and inconsistent finishes. That’s exactly where Swiss CNC machining for long parts shines. Built around a sliding headstock and a guide bushing that supports the bar right at the cut, Swiss machines are purpose-built to hold tight tolerances over extended lengths, without babying the process or slowing it to a crawl.

What Makes Swiss Different

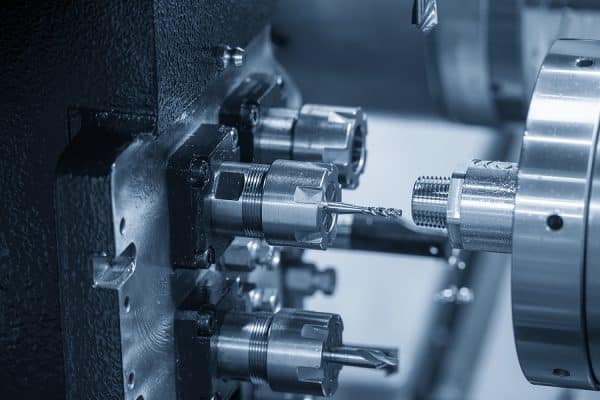

Traditional lathes grip the bar at the chuck and extend it out toward the tool. As the stickout grows, so does the risk of vibration. A Swiss-type lathe flips that setup. The bar stock is supported by a high-precision guide bushing just a few millimeters from the tool. The headstock slides, feeding fresh material through the bushing while the tools stay put. This one change, constant support at the cut, transforms how long parts are made.

The Core Advantage: Rigidity Right Where You Need It

Long, thin parts love to flex. The guide bushing cancels that tendency by clamping the bar close to the tool, dramatically reducing deflection and chatter. The payoff is immediate: cleaner surface finishes, stable dimensions, and fewer tweaks to tame vibration. If you’ve ever chased a tolerance that drifts as the tool wears or the stickout changes, Swiss machining brings that back under control.

Tolerances That Hold Over Length

Hitting ±0.0005 in on a short feature isn’t unusual. Holding tight size and true position over several inches is the real trick. The sliding headstock keeps the cutting zone consistent, so concentricity and straightness don’t wander as the cut moves down the part. That consistency is why you see Swiss machines turning out precision shafts, pins, and bone screws that have to mate perfectly end-to-end.

Faster, Not Just Finer

Swiss machines aren’t only about accuracy. They’re built for speed through parallel operations. With main and sub-spindles, live tooling, and multiple tool posts, a machine can rough, finish, drill, and mill different features at the same time. Parts often transfer to the sub-spindle for back-working while the next piece starts on the main. The result is short, predictable cycle times even on complex geometries.

Better Surface Finish With Less Polishing

Because the cut is steady and chatter is controlled, finishes come off the machine closer to final. That means less secondary polishing or centerless grinding, especially on cosmetic or bearing surfaces. Over a long production run, shaving off a finishing step can be the difference between a good price and a winning one.

Stable Unattended Production

Swiss turning pairs well with bar feeders and in-process monitoring. Once the process is dialed, the machine can run lights-out to build buffer stock or absorb a rush order. Tool-life management and probing (when equipped) help catch drift before it turns into scrap, making unattended time productive instead of risky.

Complex Geometry In One Setup

Modern Swiss platforms carry live tools for cross-holes, flats, slots, threads, knurls, and milled features. With synchronized spindles and C/Y axes, many parts that used to require both turning and secondary milling now finish in one machine. Fewer setups mean less handling, tighter cumulative tolerances, and a shorter path from raw bar to boxed parts.

Material Flexibility

From free-machining brass and aluminum to stainless steels, titanium, and nickel alloys, Swiss machines handle a wide range of materials used in medical, aerospace, automotive, electronics, and instrumentation. The guide bushing again matters here: it tames tough or springy materials that otherwise fight you on length.

Typical Use Cases

Engineers turn to Swiss CNC machining for long parts when they need:

- Precision shafts, drive pins, and axles with tight runout and straightness.

- Bone screws, dental components, and arthroscopic instruments with fine threads and close finishes.

- Connector pins and contact bodies with deep, consistent chamfers and small cross-holes.

- Valve components, nozzles, and micro-features that blend turned and milled geometry.

Each of these benefits from rigid support, consistent tool engagement, and multi-axis capability in one envelope.

Design Tips to Get the Most From Swiss

A few small choices in the print can unlock big gains:

- Favor consistent diameters and gentle transitions. Sharp steps and long, thin unsupported sections are harder to stabilize.

- Add small undercuts or reliefs where tool break-in and blend points need a place to hide.

- Specify achievable radii and thread reliefs; this speeds tool selection and reduces custom grinding.

- Call out critical datums and functional fits clearly. Your machining partner can hold them if they know exactly what matters.

- When possible, size features to standard drills, thread forms, and broaches used on Swiss platforms to streamline setup.

Quality Is Built Into the Process

Because Swiss machining often targets regulated industries, Swiss CNC machining services typically include in-process SPC, automated gauging for critical features, and robust first-article documentation. When the process is stable at the cut, the measurement data looks the same: tight distributions, minimal drift, and fewer surprises on capability studies.

Cost Drivers to Watch

Swiss machining is efficient, but like any process, a few factors move the number:

- Total length and diameter ratio. The more extreme the ratio, the more cycle time and tool strategy matter.

- Feature count and milling content. Cross-holes, slots, and complex back-working add value and time.

- Material and bar quality. Straight, consistent bar stock pays for itself in uptime and finish.

- Lot size. Set up spreads best across repeat or larger orders, though Swiss excels at both prototypes and production.

Early collaboration helps here. Share priorities—function, finish, or price—and your partner can tune the process accordingly.

When Swiss Beats the Alternatives

If your part is short and stout with heavy milling, a mill-turn or 5-axis mill may be better. But when parts are long, slender, and tolerance-sensitive, Swiss usually wins on stability, throughput, and total cost. It’s the right hammer for that very specific nail.

Swiss CNC machining for long parts delivers rigidity at the cut, repeatable tolerances over length, faster cycle times through parallel operations, and finishes that often skip secondary steps. Pair those fundamentals with capable Swiss CNC machining services, bar feeding, in-process control, and lights-out reliability, and you get predictable quality at scale.

If you’re battling deflection, inconsistent dimensions, or slow, multi-setup workflows on long components, it’s time to put a Swiss process on the print and see what changes.

Ready to talk about machining? Contact C. Thorrez Industries.