In today’s competitive manufacturing environment, productivity, accuracy, and turnaround time matter more than ever. One of the most effective ways to meet these demands is through CNC turning—a method that’s known for producing precise, repeatable parts at scale. But the key to truly unlocking its potential lies in maximizing efficiency with CNC turning.

Whether you’re running a high-volume production line or crafting complex prototypes, improving your CNC turning process can lead to better quality, reduced waste, and lower costs. In this guide, we’ll walk through CNC turning best practices, explore how it complements precision milling, and show how you can elevate your manufacturing workflow.

What Is CNC Turning?

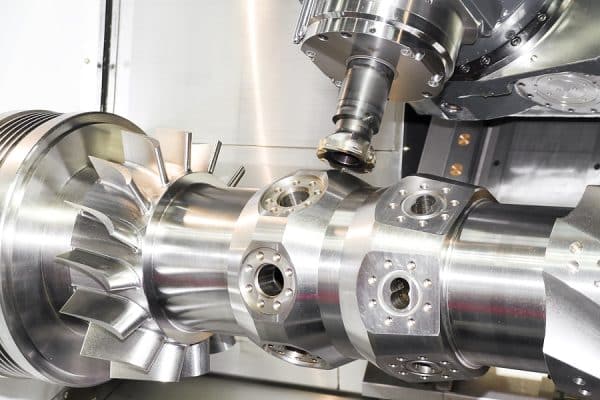

CNC (Computer Numerical Control) turning is a subtractive machining process in which a cutting tool removes material from a rotating workpiece to create a cylindrical part. It’s widely used for shafts, bushings, pins, and threaded components, and it’s especially ideal for symmetrical pieces that demand tight tolerances.

At C. Thorrez Industries, Inc., CNC turning is part of our core machining expertise. We utilize state-of-the-art lathes equipped with live tooling and multi-axis capabilities to produce everything from simple pins to complex, contoured components. But what sets high-performance turning apart is not just the equipment—it’s how efficiently and strategically it’s used.

Why Efficiency Matters in CNC Turning

Time is money. Every second spent adjusting tooling, correcting defects, or reworking parts adds up. Maximizing efficiency with CNC turning means more than just moving faster—it means eliminating unnecessary steps, preventing errors before they happen, and using the right tools and strategies to achieve consistency at scale.

Here are just a few benefits of focusing on CNC turning efficiency:

- Reduced cycle times

- Lower material waste

- Improved surface finish and part quality

- Increased equipment lifespan

- Higher overall throughput and profitability

Let’s break down the best ways to get there.

CNC Turning Best Practices

Let’s take a look at CNC turning best practices:

Optimize Toolpath Programming

Toolpath efficiency starts at the software level. Using CAD/CAM systems with advanced toolpath generation can reduce air cutting, minimize tool travel, and maintain optimal engagement with the material. Simple adjustments—like reducing rapid traverse moves or choosing more efficient tool entry points—can shave seconds off each cycle.

At C. Thorrez Industries, our programmers work closely with machinists to fine-tune toolpaths before a single part is run. That level of collaboration helps minimize trial-and-error and ensures faster ramp-up times on new jobs.

Select the Right Tooling for the Job

Tooling choice directly affects speed, accuracy, and surface finish. High-performance carbide inserts, coated tools, and optimized geometries can dramatically increase cutting speed while reducing wear. For tight-tolerance components, investing in the right tools upfront often results in fewer rejections and better part repeatability.

Tool life monitoring also plays a big role in CNC turning best practices. Setting up predictive maintenance schedules based on real-time wear data helps prevent tool breakage and surprise downtime.

Minimize Setup Time

Quick-change tooling systems, modular fixturing, and pre-set toolholders help reduce changeover time between jobs. If your team spends more time setting up than cutting, you’re losing valuable machine hours.

We use standardized setup sheets and tooling kits to reduce variation between runs. Consistency in setup leads to better first-article approval rates and smoother production.

Maintain Consistent Workpiece Quality

Starting with quality raw materials ensures fewer defects downstream. But even high-grade materials can be compromised if not handled properly. Monitor for material warping, burrs, or surface inconsistencies that may affect clamping or concentricity.

Using automated probing and in-process measurement systems also helps ensure each part stays within spec, reducing the need for manual inspection and rework.

Pairing CNC Turning with Precision Milling

In many projects, CNC turning doesn’t stand alone. It often works hand-in-hand with precision milling to produce complex geometries, multi-face machining, or features that require three- or four-axis movement.

Combining both services under one roof, like we do at C. Thorrez Industries, reduces lead time, improves tolerances, and creates a seamless flow from raw material to finished part. A turned shaft with milled keyways, for example, can move from one machine to the next without leaving the shop floor.

This integrated approach to precision machining allows for better quality control, faster project turnaround, and more accurate assemblies for our customers.

Common Challenges in CNC Turning—and How to Avoid Them

Even the most advanced CNC turning setups can hit snags. Here are some common pitfalls that hurt efficiency—and how to stay ahead of them:

- Vibration and chatter: Often caused by improper tool engagement or unstable setups. Use the right tool, overhang, and support materials well.

- Tool wear: Running tools past their prime leads to poor finishes and missed tolerances. Always monitor tool life and replace based on data, not guesswork.

- Coolant issues: Proper coolant delivery is critical to chip evacuation and thermal control. Invest in high-pressure systems and regularly clean nozzles.

- Poor documentation: Inconsistent setup sheets, missing inspection plans, or unclear part drawings slow everything down. Standardizing process documentation keeps everyone aligned.

At Thorrez, we treat problem-solving as a core part of our continuous improvement process. Small tweaks and lessons learned on one job can be rolled into the next to keep every process moving forward.

CNC Turning in a High-Mix, Low-Volume Environment

While CNC turning is often associated with high-volume manufacturing, it’s also incredibly valuable in high-mix, low-volume environments where flexibility matters. Short-run orders, prototypes, or parts with frequent design updates all benefit from fast changeovers and programmable repeatability.

At C. Thorrez Industries, we’ve built our shop to adapt quickly—whether it’s a run of 500 or a dozen specialty parts. Having both agility and efficiency means we don’t sacrifice speed for quality.

Building Long-Term Value with Smarter Turning

Maximizing efficiency with CNC turning isn’t about rushing through jobs—it’s about working smarter at every step. From toolpath optimization to tooling selection, in-process monitoring to cross-capability with precision milling, the right approach turns CNC turning into a long-term value engine for your business.

When done right, it reduces downtime, improves part quality, and gives your team the confidence to scale production when you need it most.

Ready to Take Your Machining to the Next Level?

Whether you’re looking for CNC turning support, integrated precision machining, or full part production, C. Thorrez Industries, Inc. is here to help. We combine technology, craftsmanship, and decades of know-how to deliver parts that meet your specs—and exceed your expectations.

Contact us today to discuss your next project or request a custom quote.

Let’s build something precise, efficient, and built to last.