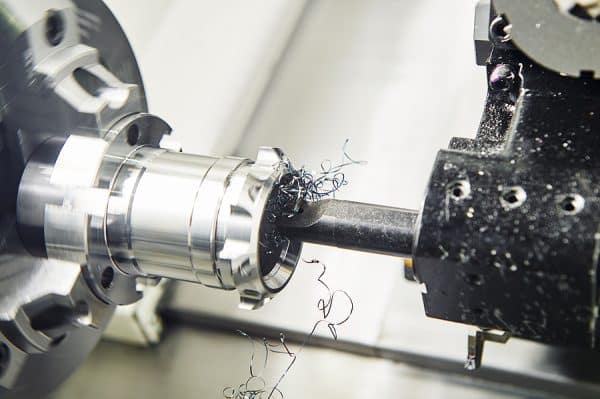

In the world of manufacturing, achieving precision is not merely an advantage but a necessity, especially in industries such as aerospace, automotive, and healthcare where the quality and accuracy of each component can be critical. This is where CNC (Computer Numerical Control) Machining becomes pivotal.

CNC machining stands out as a sophisticated technology designed to meet the rigorous demands of modern manufacturing. It provides a level of precision and efficiency that traditional methods simply cannot match.

At its core, CNC machining is celebrated for its exceptional precision. With advanced software, these machines can produce parts that adhere strictly to specified measurements, achieving tolerances that are often impossible by hand. This precision is particularly vital in industries like aerospace, where even the slightest deviation can lead to significant failures.

Furthermore, the versatility of CNC machines is a notable advantage. They can work with a variety of materials, from basic plastics and metals to exotic alloys and composites. This flexibility allows manufacturers to use the optimal material for each specific application, whether it requires the lightness of aluminum, the strength of titanium, or the heat resistance of ceramics.

Benefits of CNC Machining

Below are a few of the main benefits of CNC machining services:

- Speed and Precision: CNC machining is renowned for its rapid production capability and exceptional repeatability. Designs programmed into the CNC machine enable the production of parts with consistent quality, crucial for large-scale manufacturing where uniformity is essential.

- High Tolerances: Known for achieving high tolerances, CNC machines meet rigorous specifications required by critical industries such as aerospace and medical devices, where even minimal deviations can be consequential.

- Material Versatility: CNC machines handle a diverse spectrum of materials, from traditional metals like aluminum and steel to advanced plastics and composites. This flexibility allows manufacturers to choose the optimal material based on specific project needs like durability, weight, and environmental resistance.

- Superior Surface Finish: Besides precision cutting, CNC machines excel in achieving excellent surface finishes, often reducing or eliminating the need for post-processing. This capability is valuable in creating parts that are not only functional but also aesthetically pleasing.

Applications of CNC Machining

CNC machining is indispensable across various manufacturing aspects:

- Functional Parts: CNC machining is preferred for parts that require exact functional specifications, ensuring they operate precisely as intended.

- Prototyping: Ideal for developing prototypes, CNC machining provides a fast and accurate method to create functional prototypes, allowing for effective testing and iterative design improvements.

- Metal and Plastic Components: With the ability to precisely machine both metals and high-performance plastics, CNC machining is crucial in sectors like automotive and consumer electronics, where component reliability is key.

- Low to Mid-Volume Production: Beyond prototyping, CNC machining is cost-effective for low to mid-volume production, offering a perfect balance between quality, speed, and cost.

CNC Machining Provides Efficiency and Consistency

One of the primary benefits of CNC machining is its ability to streamline production processes. Unlike manual machining, which requires extensive operator input and constant supervision, CNC machines are programmed to carry out complex operations with little human intervention.

Consequently, the technology significantly reduces the likelihood of human error, enhancing the consistency of the output across every manufacturing batch.

Moreover, CNC machines operate around the clock with minimal downtime, effectively increasing production rates. This relentless productivity is crucial for businesses scaling operations or working under tight deadlines.

As a result, manufacturers can deliver products faster and more reliably, boosting overall business efficiency.

Enhanced Complexity with Reduced Cost

CNC machining not only enhances the quality of products but also allows for the creation of complex designs that would be too difficult or impossible to achieve through conventional machining.

Multi-axis CNC machines can rotate parts over multiple axes, enabling the tool to reach all surfaces. This capability allows for the manufacturing of intricate and detailed designs without sacrificing speed or accuracy.

Interestingly, while CNC machining is a significantly advanced technology, it can also be cost-effective.

Initially, setting up CNC machinery involves a substantial investment. However, the reduction in manual labor, coupled with decreased waste of materials and increased production speed, leads to savings over time.

Additionally, the precision of CNC machining minimizes costly errors, further reducing overall expenses.

Benefits of CNC Machining

The benefits of CNC machining are not just theoretical but are evident in real-world applications. For instance, in the automotive industry, where parts need to be both strong and lightweight, CNC machining allows for the production of complex, durable parts that meet strict safety and performance standards.

Similarly, in the medical field, CNC machines produce intricate and highly reliable components used in medical devices, from surgical instruments to implants, where precision is crucial for patient safety.

According to a report by Fortune Business Insights, the global CNC (Computer Numerical Control) machines market size was valued at USD 80.44 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2022 to 2029, reaching USD 117.65 billion by the end of the forecast period. This growth is indicative of the increasing reliance on automated manufacturing processes in industries aiming to enhance precision and efficiency.

Ready to Experience the Precision Manufacturing of Thorrez Industries?

If precision, efficiency, and quality are what you seek in your manufacturing processes, look no further than Thorrez Industries. We invite you to discover how our CNC machining services can transform your production capabilities.

Contact Thorrez Industries today to learn more about our services or to get started on your next project. Let Thorrez Industries be your partner in achieving manufacturing excellence.