In modern manufacturing, precision is everything. Whether you’re building aerospace components, automotive parts, or surgical tools, even the slightest deviation from spec can mean the difference between success and failure. That’s why precision machining is at the core of so many industries that depend on tight tolerances and consistent performance. The role of hard turning in achieving high precision makes it one of the most effective and efficient methods for working with hardened metals and heat-treated components.

So, what exactly is hard turning, and why has it become such a go-to solution for achieving precision and durability? In this post, we’ll break down the role of hard turning in achieving high precision, why it’s a standout among high-precision machining techniques, and how it supports better performance, longer part life, and smarter manufacturing overall.

What Is Hard Turning?

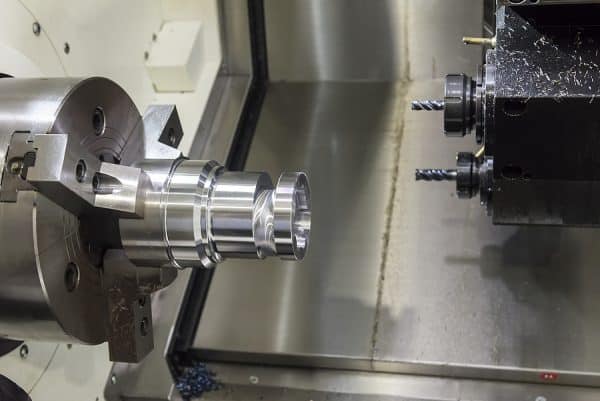

Hard turning is a metal-cutting process that allows manufacturers to machine parts after they’ve been heat-treated, typically at hardness levels above 45 HRC. Instead of grinding, which traditionally handles hardened components, hard turning uses exceptionally durable tooling, such as cubic boron nitride (CBN), to machine the part directly on a lathe. This eliminates the need for multiple operations or machine transfers, often enabling a component to go from rough to finished in a single setup.

The value here is twofold. First, hard turning reduces the time and cost involved in machining hardened metals. Second, it can achieve surface finishes and dimensional tolerances that rival, and sometimes surpass, grinding, making it a top-tier option in the world of precision machining.

Why High-Precision Machining Techniques Matter

Industries today face growing demands for more precise, more durable, and more complex components. From the high temperatures inside a jet engine to the constant motion of automotive drivetrains, parts need to hold their shape, withstand wear, and stay within microns of the original spec. That’s a tall order, especially when you’re working with materials designed to be tough, like hardened steels or nickel alloys.

This is where high-precision machining techniques become essential. Manufacturers need methods that can meet these demands without adding cost, time, or unnecessary steps. Hard turning meets that challenge by offering a way to handle post-heat-treated parts with high accuracy and speed, without sacrificing surface quality or part integrity.

The Role of Hard Turning in Achieving High Precision

One of the most compelling advantages of hard turning is its ability to achieve extremely tight tolerances, often within ±2 microns. That level of precision is critical in applications where even a small deviation could affect performance, such as fuel system components, bearing races, or transmission shafts. Unlike traditional turning or rough machining, hard turning doesn’t compromise just because the material is tough.

Surface finish is another area where hard turning shines. Under optimized conditions, it can produce a finish with roughness values as low as 0.2 microns. That’s smooth enough to meet finish requirements on parts that previously would have needed a separate grinding pass. In many cases, manufacturers can eliminate grinding entirely, cutting down on machine time, labor, and cost.

Hard turning also offers process simplicity. Complex geometries that once required multiple setups across different machines can often be completed in one operation. This reduces the risk of human error, improves concentricity, and helps ensure that parts come off the line exactly as designed. Because the process is run on CNC lathes, it also provides the flexibility to make fast adjustments to tool paths, speeds, and feeds, perfect for short runs or rapid prototyping.

How Hard Turning Boosts Durability

Precision isn’t just about measurements; it’s also about performance over time. One of the lesser-known benefits of hard turning is its impact on part durability. The process creates favorable residual compressive stresses in the surface layer of the component. These stresses help resist fatigue, cracking, and wear, which is especially valuable in parts subjected to cyclic loading or high-friction environments.

This means that parts machined with hard turning don’t just fit better, they last longer. In sectors like aerospace or automotive, where reliability can be a matter of safety or warranty compliance, this added durability makes hard turning a smart choice. And unlike grinding, which can introduce heat damage or microcracks, dry hard turning maintains surface integrity while eliminating the need for coolants or post-processing.

Where Hard Turning Makes an Impact

Hard turning is used across industries that rely heavily on precision machining. In automotive manufacturing, it’s used to produce critical powertrain and drivetrain parts such as camshafts, gear hubs, and bearing journals. In aerospace, hard turning is essential for components that must hold up under intense pressure and heat, like turbine disks and landing gear components.

The medical industry also uses hard turning for implants and surgical tools that demand extremely high accuracy and biocompatibility.

Tool and die shops benefit as well. Since many dies and molds are made from hardened materials, hard turning offers a faster way to machine finished profiles after heat treatment, helping reduce time to market and minimizing the need for costly electrical discharge machining (EDM).

Choosing the Right Time for Hard Turning

While grinding still has a place, particularly for parts requiring sub-micron surface finishes or extremely fine tolerances, hard turning has proven to be the better option in many scenarios. It’s ideal when you’re working with hardened materials, need to reduce your turnaround time, or want to streamline production by doing everything in a single setup. It’s also more adaptable when designs change or small-batch production is required, giving you more flexibility without sacrificing precision.

The key is knowing when and how to use hard turning to your advantage. This means selecting the right tooling, optimizing cutting parameters, and partnering with a machining expert who understands the full range of what hard turning can do.

Why C. Thorrez Industries Inc. Is Your Precision Machining Partner

If you’re looking to improve your machining process, reduce costs, or push your tolerances to the next level, C. Thorrez Industries Inc. is here to help. With decades of experience in precision machining and advanced high-precision machining techniques, our team specializes in hard turning solutions that meet your toughest requirements.

At C. Thorrez Industries Inc., we don’t just machine parts, we solve problems. Our engineers work closely with clients to understand your goals, whether you’re optimizing for speed, quality, durability, or all of the above.

Using advanced CNC equipment, carefully selected tooling, and real-time process monitoring, we deliver consistent results for parts that matter most. Whether you need a single prototype or thousands of components, Thorrez has the tools and expertise to make your project a success.

We’ve helped clients across the automotive, aerospace, energy, and medical sectors meet tight deadlines and complex specs without compromising on quality. Our hard turning capabilities are a cornerstone of that success, helping customers replace grinding, reduce lead times, and produce stronger, more reliable parts.

Let’s Build Better Together

If you’re ready to explore the role of hard turning in achieving high precision for your next project, or just want to learn how to streamline your current process, contact C. Thorrez Industries today. Our team is standing by to help you implement the right machining strategy for your materials, your specs, and your goals.

Let’s bring your toughest components to life with smarter, faster, and more durable solutions.