When it comes to mechanical reliability, few things matter more than high-quality threads. Whether you’re building aerospace components, automotive parts, or medical devices, the way a thread is cut or formed can make or break the part, literally. In today’s world of precision machining, manufacturers rely on advanced threading techniques for enhanced performance to ensure durability, accuracy, and longevity.

Thanks to innovations in CNC threading for precision parts, shops can now produce threads that meet strict tolerances, withstand intense torque, and resist fatigue—all while reducing cycle times and improving consistency. But not all threading methods are created equal, and choosing the right one is key to optimizing component performance.

Why Threading Technique Matters

Every threaded connection has a purpose—whether it’s holding a jet engine together or sealing fluid lines in a high-pressure system. In these applications, failure is not an option. If a thread is too loose, it can back out or leak. If it’s too tight, it might strip or seize. That’s why modern machining facilities focus so heavily on the threading process. It’s not just about cutting a spiral, it’s about engineering performance into every component.

Threading errors can lead to functional failures, rejected parts, or expensive rework. But when executed properly, precision threading ensures parts assemble perfectly every time, even across high-volume production runs. The rise of CNC technology has made this kind of repeatable accuracy the industry standard.

Methods of CNC Threading for Precision Parts

CNC machining offers a range of techniques to create high-performance threads, each suited for specific materials, volumes, and design needs.

Tapping is one of the most widely used methods for internal threads. It involves using a tool with pre-cut threads that mirrors the final thread shape. Rigid tapping, a process where the spindle and feed rate are synchronized, provides extremely accurate results. This is especially useful for blind holes, where maintaining alignment and avoiding over-cutting is critical.

Thread milling is another valuable option, especially for parts that require flexibility in diameter or depth. With thread milling, a rotating tool moves in a helical pattern to form threads. This technique offers a high degree of control, allowing machinists to cut both internal and external threads with precision. It also reduces the risk of tool breakage and is ideal for hard materials or parts that need fine surface finishes.

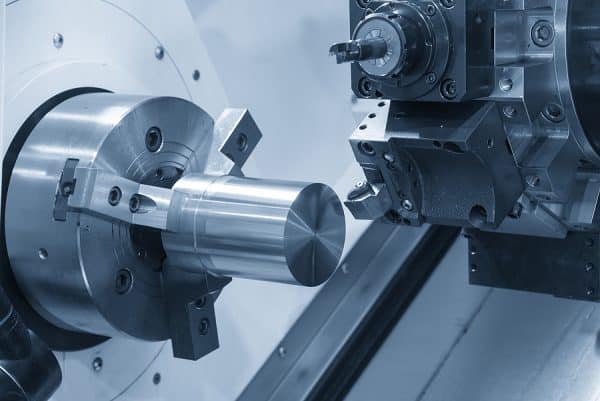

Single-point threading, often performed on CNC lathes, uses a single cutting insert to create threads gradually over several passes. This method is typically reserved for custom or large-diameter threads where precision is more important than speed. It provides excellent surface finishes and allows for tight control over the thread profile and pitch.

Thread rolling, also known as thread forming, is a non-cutting process that forms threads by pressing a die into the material. This technique cold-works the material, which not only creates the thread shape but also increases its strength. Threads made by rolling are denser and more resistant to fatigue and stripping compared to cut threads. It’s a common choice for mass production in ductile metals.

How to Choose the Right Threading Technique

Selecting the best threading method depends on several key factors, including the material being machined, the volume of parts needed, the specific thread geometry, and the part’s functional requirements.

For example, thread milling is often favored in low- to mid-volume runs where flexibility is important. It’s a great choice when the design may change or when multiple thread sizes are needed in one job. On the other hand, tapping is faster for high volumes of simple internal threads, especially in aluminum or mild steel.

Single-point threading is ideal when working with custom parts, unique profiles, or threads that require absolute control.

For maximum durability in large-scale production, thread rolling stands out as the best method, especially when you want increased tensile strength and superior fatigue resistance.

Ultimately, the decision isn’t just about speed or cost; it’s about matching the threading method to the mechanical demands of the finished component.

Precision Machining and the Labor Market

According to the U.S. Bureau of Labor Statistics, the demand for CNC tool programmers, many of whom are responsible for complex threading operations, is projected to grow by 15% from 2022 to 2032. This growth rate is much faster than average and reflects the increasing reliance on CNC processes for producing high-performance, precision components (BLS.gov).

As industries continue to prioritize quality, reliability, and lean manufacturing principles, CNC threading for precision parts becomes more essential. The threading technique chosen not only affects part performance but also influences overall production efficiency, cost, and long-term part behavior.

How to Improve Thread Performance

To achieve the best possible thread performance, it’s important to invest in quality tooling and machine programming. Choosing carbide or coated tools matched to your thread geometry and material will go a long way in reducing wear and improving thread quality.

Modern CNC machines offer canned threading cycles, such as G76 or G33, that automate the threading process while allowing tight control over feed rates, depth of cut, and pass counts.

Cutting parameters matter, too. If you’re thread milling hardened steel, for example, slower speeds and specific chip loads will improve tool life and surface finish. For tapping, synchronized spindles reduce torque spikes and prevent tap breakage.

Coolant strategy is another often-overlooked factor. For deep or blind threads, high-pressure coolant or air blast can help evacuate chips and prevent tool damage.

Lastly, inspection and measurement should never be skipped. Thread gauges, micrometers, or coordinate measuring machines (CMMs) should be used to verify form, pitch, and fit, especially for mission-critical components. For high-reliability parts, relying on “test fits” isn’t enough.

Real-World Threading Success Stories

In the aerospace industry, manufacturers rely on thread milling to produce multi-lead threads that need micron-level accuracy. This approach ensures parts like fuel system connectors won’t leak or vibrate loose in flight.

Automotive production lines use rigid tapping to machine thousands of identical threads in fuel injectors, crankcases, and transmission housings. These threads must perform under high pressure and thermal stress without stripping or backing out.

In power tools and industrial fasteners, rolled threads offer unmatched fatigue resistance, perfect for high-torque, high-cycling applications.

These examples demonstrate how the right threading method improves not just performance, but also product life and safety.

Smart Threading for Industry 4.0

Threading techniques are evolving alongside other smart manufacturing technologies. Newer CNC machines can detect tool wear in real-time and automatically adjust feed rates or depth of cut to maintain accuracy. In-process metrology ensures that threads are measured and verified during the cut, not just afterward. This kind of digital integration minimizes scrap, reduces downtime, and ensures consistent thread quality across thousands—or millions—of parts.

Software now allows for digital twin simulation of threading paths before the part ever hits the machine. This gives engineers and machinists a way to predict performance, reduce tool breakage, and avoid costly errors during setup. With these advancements, precision machining is no longer just about what happens at the spindle—it’s a data-driven process from start to finish.

Is It Time to Upgrade Your Threading Process?

Threading techniques for enhanced performance are not one-size-fits-all. They are tailored solutions that directly impact the strength, function, and reliability of your machined components. From aerospace bolts to medical screws, the choice of threading method influences how your product performs in the real world.

With the right equipment, programming, and inspection, your shop can consistently deliver threads that do more than connect; they hold everything together. And in the world of precision manufacturing, that makes all the difference.

If you’re seeing high scrap rates, inconsistent fit, or excessive thread wear, it might be time to re-evaluate your threading technique. Investing in advanced CNC threading for precision parts can reduce defects, boost efficiency, and improve the long-term reliability of your components.

At C. Thorrez Industries, Inc., we specialize in delivering advanced threading capabilities using cutting-edge CNC systems and proven process control. Whether you need custom thread profiles or high-volume production, we’re here to help you find the method that matches your goals.

Need better threads that hold strong under pressure? Let’s make it happen. Contact us today and discover what next-level precision machining can do for you.