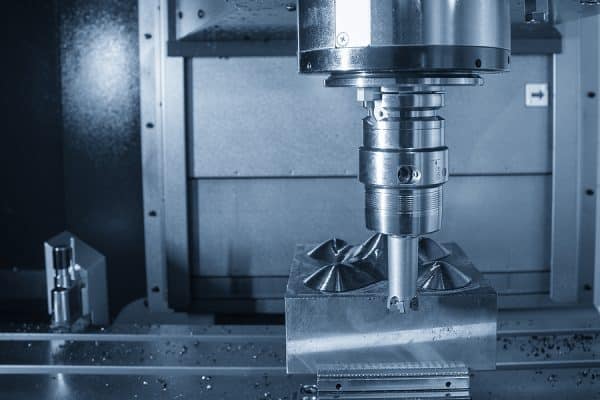

When you keep CNC milling design guidelines in mind, you end up with parts that are not only functional but also faster to produce, more affordable, and less prone to defects. Let’s walk through some key considerations for designing CNC milling-friendly parts in a way that’s clear and conversational.

Why Designing with CNC Milling in Mind Matters

CNC milling is an incredibly versatile precision machining process. It can create flat faces, slots, pockets, and complex 3D geometries with remarkable accuracy. But every process has limits. Milling relies on round cutting tools, and the way those tools move and cut through material shapes what’s realistic, and what isn’t.

If you ignore these realities, you’ll likely end up with designs that look great on paper but require unnecessary setups, custom tooling, or worse, parts that can’t be manufactured at all. By designing with the process in mind, you set yourself up for smoother production, fewer headaches, and parts that actually perform the way you intended.

Keep Corners Rounded

One of the first and most important tips in CNC milling design guidelines is to design with the cutter shape in mind. End mills are round, which means they naturally leave rounded internal corners. If you specify a sharp 90-degree internal corner, machinists can’t just make it happen with a standard tool. They’ll need to use smaller cutters, additional passes, or specialized techniques, all of which increase cost and machining time.

Instead, use generous fillets wherever possible. A larger radius allows for larger tools, which remove material faster and produce smoother finishes. In other words, rounding corners is a win for both machinists and designers.

Be Mindful of Wall Thickness

Thin walls may look efficient in a CAD model, but in the real world, they can cause big problems. During milling, thin sections vibrate or deflect under tool pressure, leading to chatter, poor surface finish, or even part failure.

As a rule of thumb, stick to at least 0.04 inches (about 1 mm) for metals and 0.02 inches (about 0.5 mm) for plastics. If strength or weight is a concern, consider reinforcing thin walls with ribs or changing the material. Keeping wall thickness consistent across the part also prevents stress concentrations and helps maintain accuracy throughout machining.

Watch Your Depth Ratios

Cavities, slots, and deep pockets often create problems in milling. Tools can only reach so far before they start to deflect or rub instead of cutting cleanly. A common guideline is to keep the depth no more than four times the width of the cavity. If you need deeper features, widening them slightly or breaking the design into multiple pieces that are assembled later can be far more cost-effective.

By respecting these ratios, you avoid fragile tools, excessive tool wear, and time-consuming multiple setups.

Reduce the Number of Setups

Every time a part has to be flipped, rotated, or re-fixtured, machining time increases and tolerances become harder to maintain. A key principle when designing CNC milling-friendly parts is to minimize the number of orientations required to complete the part.

This doesn’t mean avoiding complex geometry altogether, but if you can design features to be accessible from fewer directions, you’ll save both time and money. Parts designed for single- or double-sided machining are much more efficient than those requiring multiple setups across five or more axes.

Use Larger Radii Where You Can

Big radii mean big cutters—and big cutters mean faster machining and smoother results. Designing with small radii forces machinists to use smaller, slower tools, which increases cycle time. If your design can accommodate larger radii, it’s a simple way to reduce cost without compromising functionality.

Think about it like this: the more generous you are with your curves and radii, the less time the mill spends making passes, and the faster your part ends up in your hands.

Pay Attention to Hole Sizes and Depths

Holes may seem simple, but they carry their own set of rules. Standard drill bits come in specific sizes, so designing holes to match those sizes reduces the need for custom tools or secondary operations. Avoid holes deeper than about 10 times the diameter, since those require specialized long drills or additional processes like EDM.

Countersinks and counterbores should also follow standard dimensions when possible, making them easy to produce with off-the-shelf tooling.

Finishes and Aesthetics: Know What You Really Need

Another important part of CNC milling design guidelines is deciding on surface finishes early. An “as-machined” finish is typically more than sufficient for functional parts. But if your design requires a cosmetic or protective finish, such as bead blasting, anodizing, or powder coating, make sure you call that out clearly.

Not every face of a part needs the same finish. By limiting special surface treatments only to the areas that require them, you can keep costs down while still getting the desired look and performance.

Material Choices Matter

Different materials behave differently under the mill. Aluminum, for example, is easy to cut and forgiving, which makes it a popular choice for prototypes and lightweight parts. Stainless steel, while strong and corrosion resistant, can be tougher to machine and may increase cycle time. Titanium offers an excellent strength-to-weight ratio but requires careful planning to avoid tool wear.

When you’re designing CNC milling-friendly parts, choosing a material that balances performance with machinability can save both time and expense. If you’re unsure, consult your machining partner early in the process; they’ll know what’s practical and what’s not.

Design with Assembly in Mind

Sometimes the best way to make a complex part is not to make it all in one piece. Splitting a design into multiple components that are later assembled can simplify machining, reduce material waste, and improve tolerances.

For instance, a deep cavity might be easier to achieve by machining two shallower parts that bolt together. Not only does this make manufacturing simpler, but it also makes future maintenance and repairs more practical.

Think About Tolerances Early

Specifying tolerances is another area where design decisions have a big impact on machining. Tight tolerances require slower machining, more tool changes, and additional inspection steps. If your design calls for tight tolerances across the board, you could be driving up costs unnecessarily.

Instead, apply tight tolerances only where they’re critical to function. For non-functional surfaces, standard machining tolerances are usually sufficient. This balance ensures that critical dimensions are precise without adding unnecessary expense.

Communication Is Key

The best designs for CNC milling are created in collaboration with machinists. Don’t hesitate to reach out early in the design process to review your ideas and get feedback. Machinists can point out potential issues, suggest design changes, and recommend materials or finishes that align with both your goals and your budget.

At C. Thorrez Industries, this collaboration is part of our DNA. With decades of experience in precision machining, our team helps clients refine designs so they’re not just functional on screen but manufacturable in the real world.

Bringing It All Together

Designing with CNC milling in mind isn’t about limiting creativity. It’s about channeling it into practical, efficient solutions. By remembering to keep corners rounded, maintain reasonable wall thicknesses, respect depth ratios, minimize setups, and think carefully about materials, finishes, and tolerances, you’ll create designs that are easier and more cost-effective to produce.

These principles aren’t just rules; they’re shortcuts to smoother workflows and stronger parts. When you embrace CNC milling design guidelines, you reduce frustration, save time, and set your project up for success.

Ready to Turn Your Designs Into Reality?

If you’re working on a new part and want to be sure it’s manufacturable, C. Thorrez Industries Inc. is here to help. From designing CNC milling-friendly parts to delivering complex components with tight tolerances, we combine experience, cutting-edge equipment, and an integrated approach to precision machining.

Let’s turn your ideas into reliable parts that are built to perform. Reach out to our team today to request a quote page.